Polypropylene

Yujie Industrial modified PP utilizes a dual-track strategy: conventional modification and PCR/OBP environmentally friendly modification, focusing on recycling and functionalization to meet diverse needs.

Key information is as follows: Core Product Series

1. Conventional Modified PP: Includes high-impact, high-heat-resistant, high-rigidity, halogen-free flame-retardant (V0/V1), UV-resistant, antistatic, glass fiber reinforced, and mineral-filled models, suitable for injection molding, extrusion, blow molding, and fiber drawing.

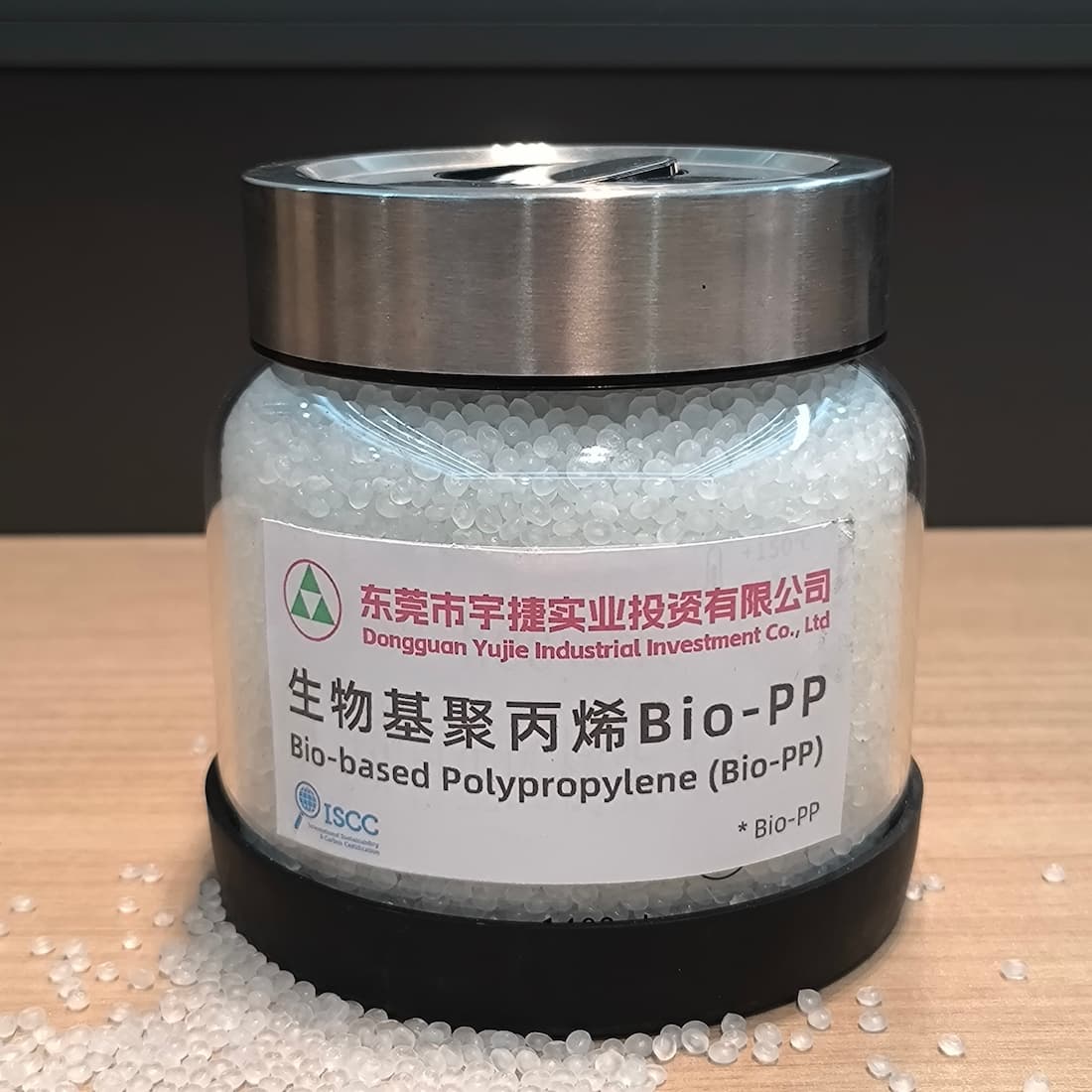

2. Environmentally Friendly Modified PP (Core): PCR post-consumer recycled (derived from food-grade waste food containers/beverage cups), OBP ocean-recycled plastics, with a recycling rate ≥20% (certified access)/≥50% (GRS mark), passing GRS/OBP/ISCC/UL 2809 standards, and TC certificates available.

3. Customized PP: Melt index, color, flame retardancy/heat resistance/impact resistance, etc., adjustable as needed, supporting food contact grade and medical grade customization. Key Performance and Advantages - Basic Performance: Chemically resistant, easy to process, low density; environmentally friendly version reduces carbon footprint by 60%+, performance comparable to virgin materials.

- Core Advantages: Full-chain traceability, physical isolation of raw materials, stable modification process; compliant with ISO14001/45001, chemicals comply with ZDHC MRSL, and passed RoHS, REACH, FDA, and other tests.

Read More