William Chen

+86 13030895350

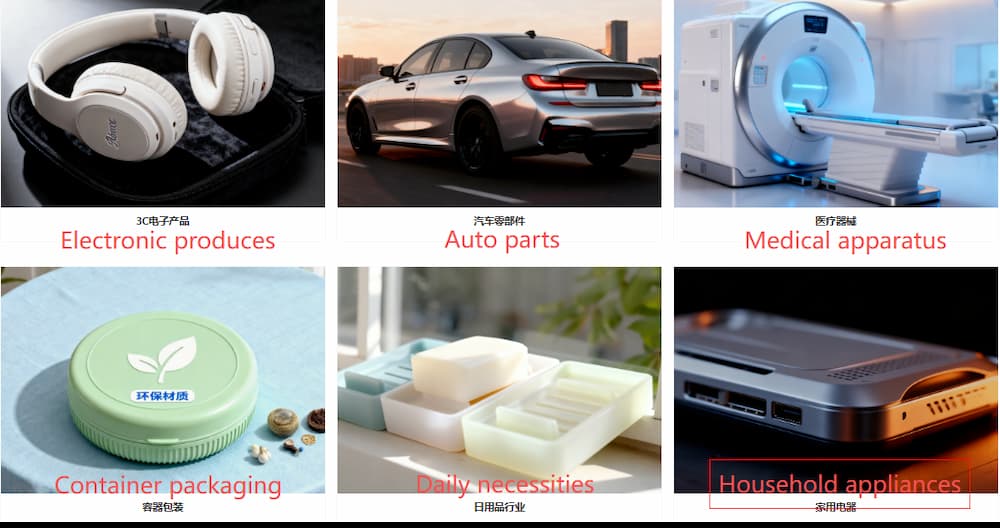

Yujie RPBT recycled PBT excellent properties make it used in the following areas:

1. Electronics and Electrical Industry (Largest Application Area)

• Connectors: This is a classic application of PBT, such as various connectors for computers and mobile phones. Requirements include dimensional stability, heat resistance, flame retardancy, and insulation.

• Switches: Switching components in home appliances and automobiles.

• Coil Bodies: The frames for transformers and relays.

• Housings: Housings for power tools and household appliances (such as hair dryers and coffee makers).

2. Automotive Industry

• Lighting Components: Bases for headlights and taillights, rearview mirrors (requiring surface electroplating).

• Sensors: Housings for various automotive sensors.

• Ignition Systems: Distributor covers, ignition coils.

• Others: Door handles, wiper arms, etc.

3. Machinery and Equipment

• Used in manufacturing parts requiring self-lubrication and low friction, such as gears, bearings, pump housings, impellers, etc.

4. Fiber Optics

• Used as a secondary coating material for optical fibers to protect them.

Item No :

RPBT recycled PBT customizedOrder(MOQ) :

25KGPayment :

DiscussProduct Origin :

ChinaColor :

NatureShipping Port :

guangdongLead Time :

3-10 working daysYujie PCR RPBT recycled PBT Characteristics and Performance Advantages:

1. Excellent Mechanical Properties:

· High strength and rigidity: PBT possesses high mechanical strength and rigidity at room temperature, capable of withstanding significant loads. · Good fatigue resistance: Suitable for manufacturing components requiring repeated movement or subjected to cyclic stress.

2. Excellent Electrical Properties:

· Excellent insulation strength and arc resistance.

· Its electrical properties remain stable even in humid and high-temperature environments. This makes it an ideal material for electronic and electrical components.

3. Good Chemical Resistance:

· Excellent resistance to water, oil, aliphatic hydrocarbons, weak acids, and weak alkalis.

· However, it is susceptible to corrosion from strong acids, strong alkalis, and halogenated hydrocarbons.

4. Low Moisture Absorption:

· Among engineering plastics, PBT has a very low water absorption rate. This means that its dimensional and performance changes are minimal in humid environments, and the drying time required before molding is relatively short.

5. Good Processing Performance:

* Short Molding Cycle: PBT crystallizes quickly, has good melt flow, and cools rapidly during injection molding, resulting in high production efficiency. * Relatively Stable Molding Shrinkage, Making Product Dimensions Easy to Control.

6. Heat Resistance:

* Heat Deflection Temperature (HDT) is between 150°C and 220°C (after glass fiber reinforcement). Long-term service temperature can reach 120°C to 140°C.

Main Disadvantages:

1. Not resistant to strong acids and alkalis.

2. Not resistant to hot water: Prolonged immersion in high-temperature hot water (above 80°C) will decrease mechanical properties.

3. Prone to Warping: Due to its crystallization characteristics, pure PBT products are prone to warping during molding.

4. Poor UV Resistance: Unmodified PBT will become brittle and discolor after long-term outdoor exposure, usually requiring the addition of UV stabilizers.

PBT Modification To overcome the shortcomings of PBT and meet specific application requirements, it is typically modified.

PBT is a crystalline engineering plastic with excellent overall performance.

Its high strength, high insulation, low moisture absorption, and ease of processing have made it an indispensable key material in the demanding electronics, electrical, and automotive industries. Through glass fiber reinforcement and flame-retardant modification, its application range has been greatly expanded.

leave a message

Scan to Wechat/Whatsapp :