William Chen

+86 13030895350

Yujie industrial is a High-quality PCR customized material manufacturer .

Yujie PCR has passed GRS、OBP、UL2809、ISCC、Carbon Footprint Certifications,

open TC certification and PCR plastic production capacity is 50000 tons of environmentally materials responding to the national carbon policy and helping low-carbon action.

Mr. Shi from Yujie Industrial, a leading plastics supplier, was invited to participate in a live broadcast on Plus.com, where he discussed the development and business opportunities of the PCR industry with Dr. Zhang. During the broadcast, Mr. Shi shared the reasons for the rise and current status of the PCR industry, analyzed potential market opportunities and bottlenecks, recounted Yujie's efforts, trials, and achievements, and expressed his vision for future development. Finally, he and Dr. Zhang called on more businesses to fulfill their social responsibility, pay attention to the PCR industry, reuse misused resources, and jointly protect our green planet.

Recently, more and more manufacturers, traders, and brand owners have begun to pay attention to PCR, GRS, UL2809, and OBP, and have many questions about them. Yujie began focusing on environmental certification early on and was among the first companies to obtain GRS certification. It has successfully launched innovative PCR products to the market, driving the development of the PCR plastics industry. Now, let's follow Yujie to understand what PCR, GRS, OBP, and UL2809 are, and the connections between them.

In simple terms, PCR (Post-Consumer Recycled Material) is a general term for post-consumer recycled and reused goods, while GRS (Good Supply Practice) and UL2809 are two environmental certification methods for recycled products, both providing supply chain traceability certification. OBP (Onshore Plastics Product) specifically refers to marine waste plastics. GRS certification is mature, widely recognized in the global market, and has high acceptance. UL2809 emphasizes the verification of the content of recycled materials in products. Focusing on the PCR industry can help us enter high-value markets and gain the attention of environmentally conscious consumers, enhancing our market competitiveness.

PCR – Post-Consumer Recycled Material

Recyclable plastics generally come in two types: one is plastic products recycled and reused after consumer use, i.e., PCR plastics; the other is waste generated during industrial production, commonly known as sprue, i.e., PIR plastics (post-industrial recycled material). Both are recycled plastics. PIR plastics are easier to process, generally requiring immediate crushing to regenerate pellets; PCR plastics have an absolute advantage in terms of the quantity that can be recycled. A vast amount of waste plastic worldwide awaits recycling and reuse, posing a significant challenge to production processes and procedures.

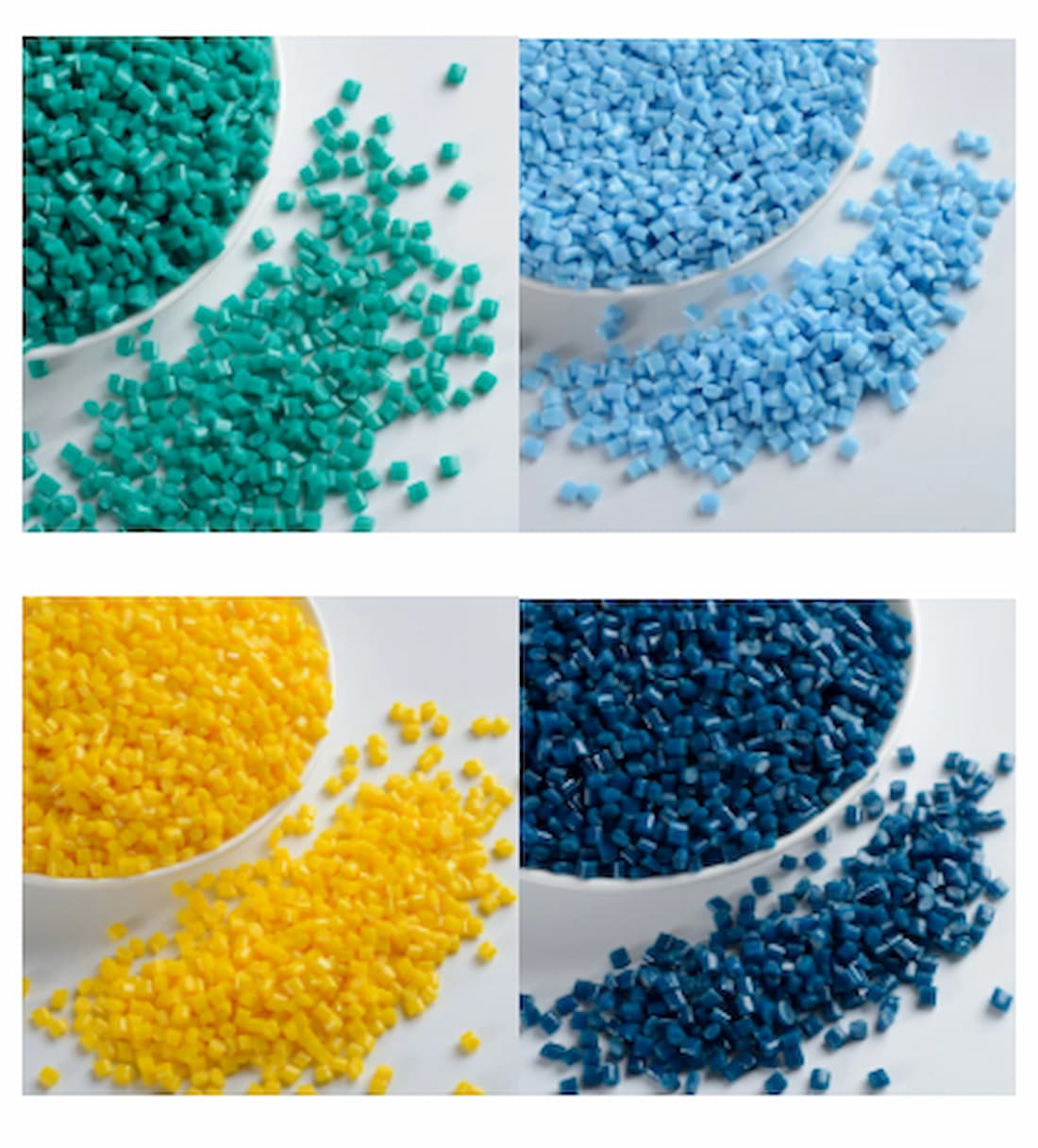

For many years, through unwavering investment in the PCR industry, Yujie has cultivated a highly skilled and experienced team, equipped with sustainable and environmentally friendly material production workshops, and continuously improved its production processes and procedures to maximize the restoration of the original properties of plastics. After initial sorting, recycled plastics undergo crushing, brine washing, and high-temperature washing before being mixed in a large mixing tank for the first time. The mixed material undergoes its first testing and grading, is packaged for later use, and qualified plastics are placed on the production platform where additives are added for a second mixing. The mixed plastics are then granulated in an extruder, undergoing dehydration, drying, and vibration processes before a third final mixing. The finished product undergoes a second testing; qualified products are packaged and shipped, while unqualified products are returned to the warehouse. It is through these three mixing processes and two testing processes that the original properties of the raw materials are preserved. Currently, Yujie can provide customized modification and dyeing services for recycled plastics and is capable of producing high-quality PCR series products with properties comparable to the raw materials. The PCR series is widely used in consumer electronics and office equipment, furniture and appliances, automotive parts, textiles, packaging, and other fields.

GRS – Global Recycled Standard

GRS certification is an international, voluntary, and comprehensive product standard that specifies third-party certification requirements in four areas: recycling content, chain of custody, social and environmental practices, and chemical restrictions. It aims to increase the use of recycled materials in products and reduce/eliminate the hazards caused by their production. It applies to products with a recycled content of 20% or more. GRS certification spans the entire supply chain, connecting all stakeholders, including raw materials, production, processing, trade, and branding. All parties participate, starting from the recycling stage, with each production stage undergoing certification, ultimately ending with the final seller in business-to-business transactions. Transaction Certificates (TCs) are used to trace the origin of materials between upstream and downstream entities.

Yujie has already obtained GRS certification this year, covering almost all major plastic types, and has become an IKEA supplier. We welcome your feedback.

Ocean Bound Plastic refers to plastics that are not properly managed, are abandoned, and transported to the ocean by rain, wind, tides, rivers, and floods, in communities or areas where waste management is lacking or extremely inefficient. Plastic waste in landfills or managed landfills is not considered OBP. To more precisely target the points of marine plastic spills in the ocean, marine plastics are subcategories: waterway marine plastics (plastic waste located in or within 200 meters of rivers) and shoreline marine plastics (plastic waste located within 200 meters inland from the highest tide line and within 100 meters outward from the lowest tide line). OBP aims to encourage the removal of marine plastics from the environment by increasing the value of effective collection and treatment. Yujie's PCR series products also include marine recycled plastics and have received professional certification.

UL 2809 – UL's Verification Statement Regarding Recycled Material Content

UL is an international third-party certification, auditing, testing, and standards development body, offering verification statements for various categories. The UL Environmental Declaration verification verifies specific environmental indicators of a product. Qualified companies or manufacturers can use the UL Environmental Declaration verification mark on product packaging and marketing materials. Verification includes aspects such as bio-based content, recyclable material content, fast-recycling materials, zero waste landfill, and VOC content. The UL Environmental Product Declaration Mark, developed according to the Product Category Rules (PCR), provides manufacturers with a reliable environmental transparency report containing environmental information throughout the product's entire life cycle (LCA), from material selection to post-use disposal. The UL 2809 certificate is a declaration of environmental verification of a product's recycled material content. It involves third-party verification of the product's pre-consumer recycled material content, post-consumer recycled material content, closed-loop recycled material content, total recycled material content, and ocean recycled plastic content to prove that the product is as environmentally friendly as claimed.

Yujie has four PCR products that have obtained UL 2809 certificates: RPC XL110, RABS XL700, RPC/ABS XL1200, and PBT PB010. PCR products contain 63% to 93% recycled materials, including post-consumer recycled plastics derived from electronics and ocean-recycled plastics. While increasing the recycled material content, the performance of the new plastics is excellent, comparable to the raw materials. They have also passed the EU's RoHS (Hazardous Substances in Electronics and Information Technology) testing and almost all industry-specific chemical testing (ReacH) standards, making them applicable to electronics, building materials, automotive parts, medical devices, and other fields.

The global rise of the PCR industry and various environmental certifications demonstrates that the circular economy, as the foundation of human survival, has become a widely accepted consensus. People's awareness of resource recycling and sustainable development is rapidly increasing, and material reuse has become an important way to rationally utilize resources, replace other products, and reduce environmental pollution. Countries around the world are enacting legislation to increase the recycling rate of materials and using economic means to encourage the reuse of recycled resources and the development of related technologies. Environmentally friendly products are more easily accepted by consumers, better meet people's growing demands for environmental protection, gain a broader market, and possess brand value.

Yujie Industrial's PCR product series has passed GRS and UL2809 certifications, fully guaranteeing the source and quality of these products. This provides downstream buyers and brand owners with reliable product assurance, meeting market demand for high-quality PCR products. Of course, Yujie will not stop there; it will continue to move forward, driving the development of the PCR industry, fulfilling its corporate social responsibility, and contributing to a greener planet.

Thank you for reading! Thank you for your support!

Best regards,

We can modified and customized for you .

Please feel free to contact us. Thank you !

William Chen Whatsapp/Wechat: +8613030895350 Email:13030895350@163.com

leave a message

Scan to Wechat/Whatsapp :