William Chen

+86 13030895350

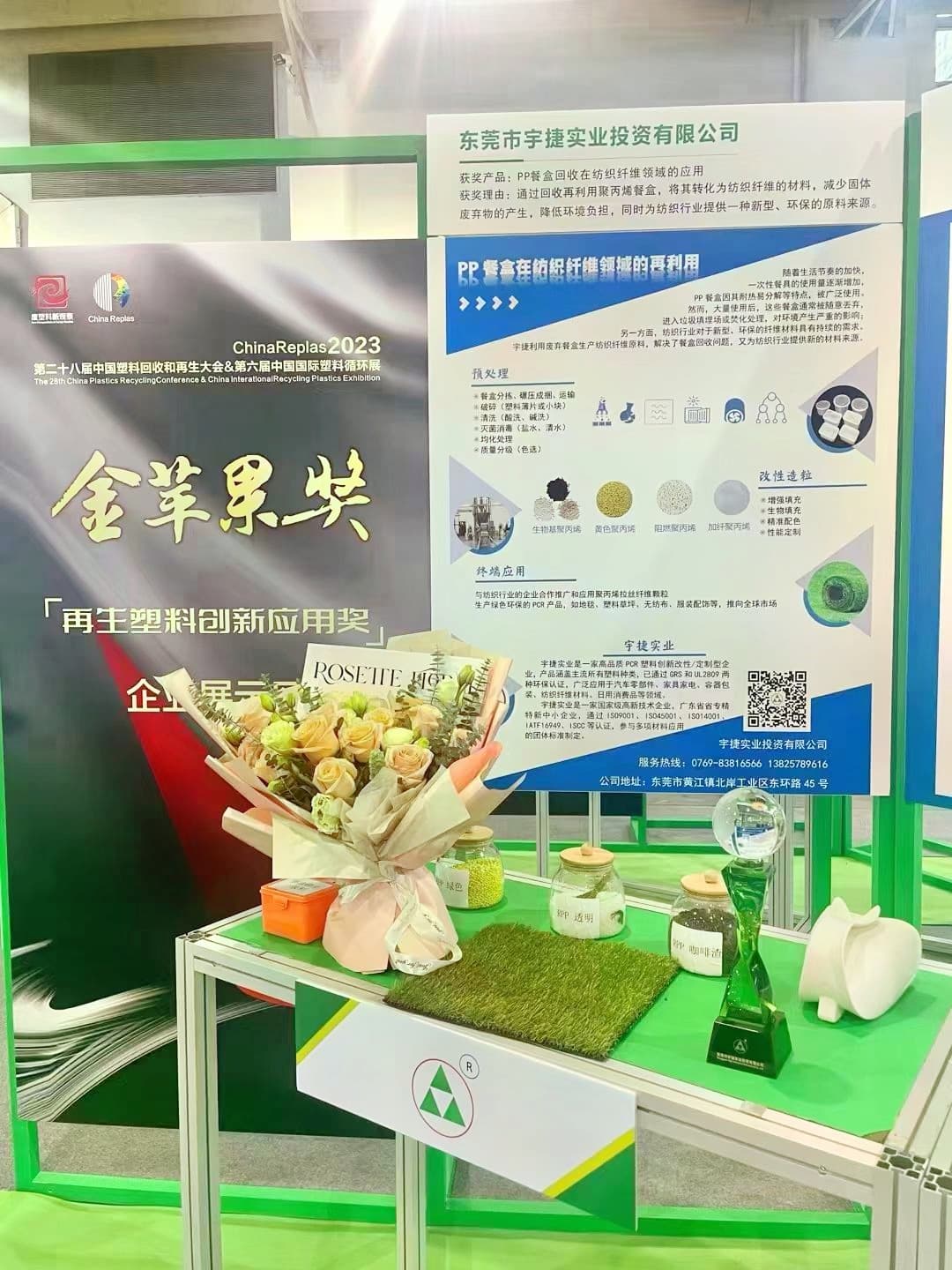

Yujie industrial is a High-quality PCR customized material manufacturer .

Yujie PCR has passed GRS、OBP、UL2809、ISCC、Carbon Footprint Certifications,

open TC certification and PCR plastic production capacity is 50000 tons of environmentally materials responding to the national carbon policy and helping low-carbon action.

Bio-based materials are materials prepared from renewable biomass (plants, microorganisms, waste oils, etc.) through bioconversion, chemical synthesis, or physical processing.

Bio-based products are wholly or partly derived from materials of biological origin (such as plants, animals, enzymes, and microorganisms, including bacteria, fungi and yeast).

Their core characteristics are low carbon, renewability, and partial biodegradability.

They are used to replace petroleum-based materials, aligning with "dual carbon" (carbon dioxide, oil, and gas) and green supply chains.

I. Core Concepts and Common Confusions

- Bio-based ≠ Biodegradable: Bio-based depends on the source of the raw materials (renewable); biodegradable depends on whether it is decomposed by microorganisms after disposal (e.g., PLA requires industrial composting, while PHA can degrade naturally).

- Ideal type: Such as PLA and PHA, combining bio-based and biodegradable properties, achieving a closed-loop carbon cycle.

- Key indicators: Bio-based content (%), carbon footprint, low-carbon certifications such as ISCC/GRS, and performance matching (compared to petrochemical-based materials).

II. Mainstream Categories and Characteristics

Category | Raw Material | Performance | Typical Application

PLA (Polylactic Acid) | Corn/Sugarcane | Transparent, good rigidity, heat resistant to approximately 60℃ | Packaging, tableware, 3D printing

PHA (Polyhydroxyalkanoate) | Microbial fermentation | Naturally degradable, biocompatible | Medical consumables, food contact

Bio-based PP/PE | Waste oil/Starch | Consistent with petrochemical-based properties, low carbon | Automotive interiors, packaging films

Bio-based PA | Castor oil/Bio-based dicarboxylic acid | High strength, wear-resistant | Automotive parts, electronic casings

Starch-based Plastics | Starch + Biodegradable polyester | Low cost, biodegradable | Disposable daily necessities

III. Core Process Paths

1. Bioconversion: Fermentation/Enzyme catalysis (e.g., starch → lactic acid → PLA, microbial synthesis of PHA).

2. Chemical Synthesis: Biomass → Platform compound (ethanol/succinic acid) → Polymerization (e.g., bio-based PE).

3. Physical Modification: Blending/Filling (e.g., starch + PLA to improve toughness and reduce cost).

IV. Market and Competition (2025 projections)

- Scale: Global bio-based plastics production is approximately 12 million tons, with China accounting for approximately 4 million tons; Bio-PP/Bio-PE accounts for approximately 30% (global ≈ 3.6 million tons, China ≈ 1.2 million tons).

- Market Structure: First tier (Borealis, BASF, etc., single-plant capacity > 300,000 tons); Second tier (Yujie, Jindan, etc., 50,000-100,000 tons); Third tier (small and medium-sized manufacturers < 50,000 tons).

- Trends: Non-grain-based (waste oil/straw), performance-enhancing modification, cost reduction (economies of scale).

V. Application Scenarios and Customer Demands

- Packaging: Food/daily chemicals/express delivery, emphasizing low-carbon compliance, biodegradability, transparency, and airtightness.

- Automotive: Interior trim/lightweight components, requiring IATF 16949 compliance, low VOCs, and a 15%-30% reduction in carbon emissions.

- Medical: Syringes/sutures, requiring medical-grade, biocompatible, and absorbable materials.

- Home Furnishings/Electronics: Casings/accessories require UL/environmental certification, weather resistance/scratch resistance modifications.

- Core Requirements: Low-carbon compliance, performance standards met, stable supply, and traceable carbon footprint.

VI. Industry Challenges and Opportunities

- Challenges: Higher costs than petrochemical-based products (10%-50% premium); performance shortcomings in some categories (e.g., low heat resistance of PLA); unstable scale and raw material supply.

- Opportunities: Driven by EU CBAM and China's dual-carbon policies; mandatory green procurement by brands; cost reduction and efficiency improvement through non-grain technology breakthroughs.

VII. Yujie Industrial has the Differentiated Path

- Non-grain waste oil (gutter oil/waste palm oil) route, with a significant carbon footprint advantage.

- Bio-based + PCR composite, complete ISCC、GRS、OBP certifications, providing CBAM compliance data.

- Modification technologies (fiber reinforcement/fire retardancy/toughening), performance comparable to petrochemical-based products, suitable for multiple scenarios.

Yujie Industrial has the non-grain waste oil raw material has a unique pathway, complete ISCC certification, modification capabilities that meet the high-end needs of automobiles and packaging, and a carbon footprint advantage that aligns with "dual carbon" and the EU CBAM. It forms a green matrix with PCR/OBP and is associated with brands such as IKEA.

Thank you for reading.

Best regards,

We can modified and customized for you .

Please feel free to contact us. Thank you !

William Chen Whatsapp/Wechat: +8613030895350 Email:13030895350@163.com

leave a message

Scan to Wechat/Whatsapp :