William Chen

+86 13030895350

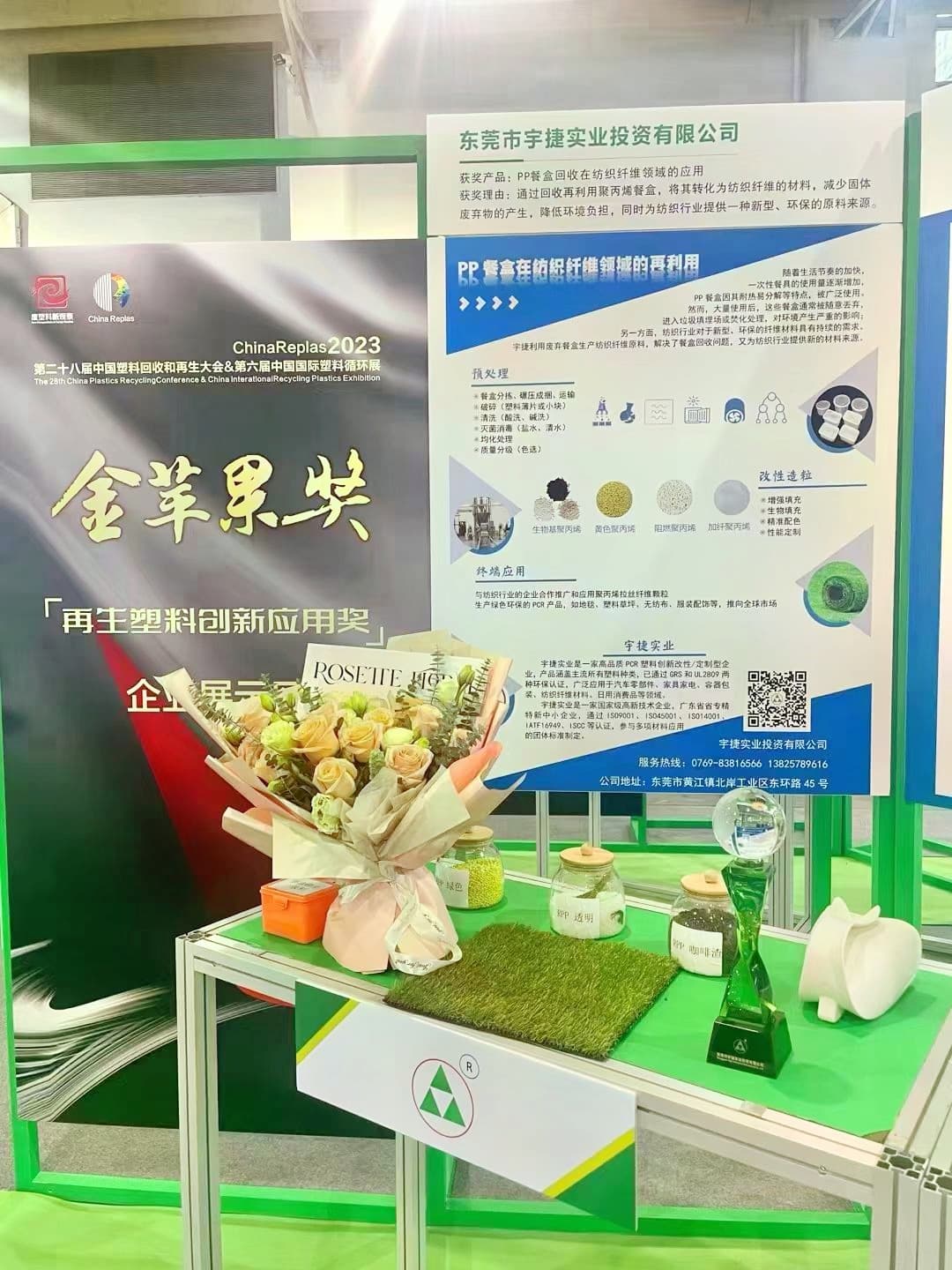

Yujie industrial is a High-quality PCR customized material manufacturer .

Yujie PCR has passed GRS、OBP、UL2809、ISCC、Carbon Footprint Certifications,

open TC certification and PCR plastic production capacity is 50000 tons of environmentally materials responding to the national carbon policy and helping low-carbon action.

Yujie Industrial recycling of discarded takeout containers, resulting in the modification and application of Recycled PP pellets (PCR-PP Post consumer recycled PP granules) , a key plastic raw material.

The Recycling Journey of Takeout Containers: From White Pollution to Recycled Polypropylene Granules Comparable to Raw Materials.

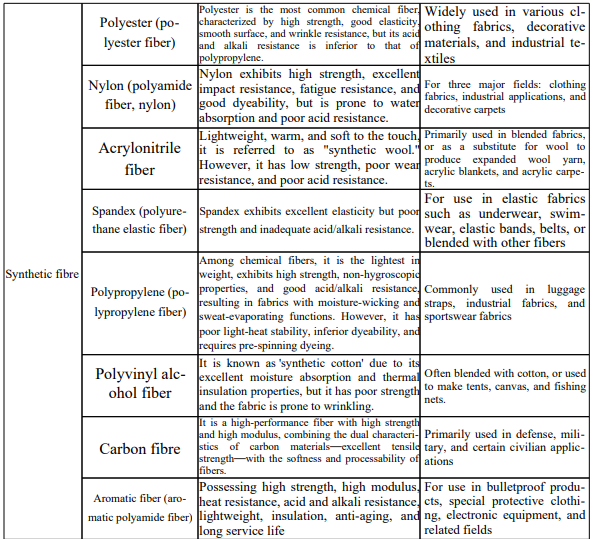

Polypropylene can be classified into five categories according to processing requirements:

Film Grade, Injection Grade, Pipe Grade, Fiber Grade, and Yarn Grade. In PCR-PP applications, the first three are well-established, with relatively standardized processes and widespread application, resulting in high familiarity. The latter two are used only in specific scenarios and fields, requiring different processing techniques for different products.

I. Fiber Grade PCR-PP(Post consumer recycled PP pellets): Polypropylene fiber, also known as polypropylene fiber, comes in long fiber, short fiber, spunbond nonwoven fabric, meltblown nonwoven fabric, and other types. Compared to other fibers, polypropylene fiber possesses the lightest, warmest, and most hydrophobic properties. Its fiber density is only 0.91 g/cm³, the lowest among the five major synthetic fibers, and approximately 34% lighter than polyester fiber. Polypropylene fiber has a thermal insulation rate of 36.49%, the highest among the five major synthetic fibers, 1.7 times that of polyester. Its standard moisture regain is almost zero, exhibiting the best hydrophobic and moisture-wicking properties. Simultaneously, polypropylene fiber has good acid and alkali resistance and heat aging resistance. With appropriate modification, it can produce high-performance weather-resistant, heat-resistant, and acid and alkali-resistant polypropylene fibers, widely used in concrete, geotextiles, sanitary materials, sportswear, and carpets.

Long fibers can be divided into ordinary long fibers and fine denier long fibers. Fine denier polypropylene fibers, with a fineness ≤2.2 dtex, possess good luster, soft hand feel, excellent drape, and low density, making them suitable for the knitting industry. They can be interwoven with cotton, viscose, silk, spandex, etc., to create cotton-covered polypropylene and silk-covered polypropylene products, ideal materials for high-end sportswear and T-shirts.

They can also be used to produce bulked continuous filament (BCF), with wide applications in decoration and clothing.Currently, 90% of global carpet backing and 25% of carpet yarn are made from polypropylene fibers.

The resulting fine denier polypropylene fibers have a good hand feel, soft texture, and gentle luster; their wicking effect gives them moisture-wicking properties.

The production process for short fibers mostly employs porous, low-speed, continuous processes, i.e., short-fiber spinning. Polypropylene short fibers blended with cotton can be used to make polypropylene-cotton fabrics and sheets; blended fibers with viscose can be used to make blankets; and pure polypropylene and blended yarns are also available. The fiber thickness for hygiene products is 1.5-2.5 dtex, while the fiber thickness for ground fabrics is 5-10 dtex.

Spunbond nonwoven fabric, also known as filament nonwoven fabric, is made by extruding, spinning, stretching, web-laying, and bonding polypropylene raw materials. It features a short process, low cost, high productivity, excellent product performance, and wide range of applications. Polypropylene nonwoven fabric is widely used in various fields of production and daily life (such as disposable medical and hygiene products, disposable protective clothing, agricultural fabrics, furniture fabrics, and shoe linings).

Meltblown nonwoven fabric technology produces very fine fibers (down to 0.25 μm). Meltblown fabric has a large specific surface area, small pores, and high porosity, thus its filtration, shielding, and oil absorption properties are difficult to achieve with nonwoven fabrics produced by other individual processes. Meltblown nonwoven fabric is widely used in medical and hygiene products, thermal insulation materials, and filter materials. Meltblown fabric is "blown" out, using a high-speed stream of hot air to stretch the polymer melt extruded from the spinneret, forming ultrafine fibers that are collected on a wire mesh or roller and bonded together. Therefore, the polypropylene used in medical and hygiene products is mainly high melt index polypropylene fiber.

In addition, polypropylene fibers are also well-suited for producing home carpets. Pile carpets are generally made from low-twist polypropylene fibers. These carpets offer properties such as heat insulation, insect resistance, easy washing, low shrinkage, and lightweight, making them ideal for home use.

Artificial turf is another application of polypropylene fibers. A plastic lawn or a pile artificial turf (called chemical grass) is made by looping polypropylene flat filaments. These artificial turfs are used in stadiums along highways, central squares, transportation hubs, and other scenic areas. Polypropylene fibers have relatively low sun resistance, so UV absorbers are added during manufacturing.

II. Filament-Grade PCR-PP(Post consumer recycled PP pellets)

Generally speaking, filament-grade RPP is mainly used in the plastic weaving industry. It is corrosion-resistant, non-absorbent, and has excellent tensile strength, making it particularly suitable for packaging bags such as FIBCs, woven bags, and heavy industrial cement bags.

Filament-grade HDPE is used for cables, nets, etc., while yarn-grade PP is used for fabric ropes, woven bags, (for sunshade or covering) tarpaulins, carpet backing (base fabric), FIBCs, tarpaulins, and rope production. These products are mainly used for packaging grains, fertilizers, cement, sugar, salt, industrial materials, and minerals.

Filament-grade PP is a major raw material for woven products. Because its processing technology is the easiest to control, most new plants produce filament-grade PP during commissioning. Its production processes mainly include liquid-phase bulk method, gas-phase method, and a combination of liquid-phase bulk and gas-phase methods. The properties and structure of PP filament-grade PP produced by different processes also vary. The melt flow index (MFI) of fiber-grade PP has a reference range of 2.5-3.5 g/10 min. Besides its application in woven product manufacturing, it can also be used to produce thick and glossy BOPP films, and can be blended with injection molding materials to produce injection molded products.

Thank you for reading!Thank you for your support!

Yujie Industrial website : www.yujiepcr.com Email: 13030895350@163.com

Please feel free to contact us : William Chen Whatsapp/Wechat: +86 13030895350

If this article was helpful, please forward and share it.

Follow us to learn more about plastics, master green information.

Share low-carbon and environmentally friendly concepts to make our lives healthier!

Yujie Industry has always put its business philosophy of "Quality, Responsibility, Innovation, and Sharing" into practice, adhering to the social belief of "Win-Win Cooperation and Eternal Integrity," and is committed to becoming a socially responsible and trustworthy high-quality enterprise.

leave a message

Scan to Wechat/Whatsapp :